-

Ocean Data Acquisition

-

Wave GliderThe Wave Glider is a low-profile, unmanned surface vehicle that is capable of long-range, extended deployments with minimal human intervention. More Information →

SeagliderOcean gliders provide dynamic, high density data sampling from the water column in near real-time, enabling timely, quantitative assessment of environmental risks. More Information →

SeagliderOcean gliders provide dynamic, high density data sampling from the water column in near real-time, enabling timely, quantitative assessment of environmental risks. More Information → OceanStarOceanStar is a field-proven marine environmental monitoring system that will provide sensor readings from the sea floor to your desktop within seconds, from anywhere in the world. More Information →

OceanStarOceanStar is a field-proven marine environmental monitoring system that will provide sensor readings from the sea floor to your desktop within seconds, from anywhere in the world. More Information → VoyagerThe Voyager drifter buoy provides near real-time ocean current, sea surface temperature and oil spill tracking data via Iridium satellite telemetry. More Information →

VoyagerThe Voyager drifter buoy provides near real-time ocean current, sea surface temperature and oil spill tracking data via Iridium satellite telemetry. More Information → TritonThe Triton telemetry buoy offers broadband data acquisition from sensors located on the buoy, suspended in the water column or on the sea floor, depending on application requirements. More Information →

TritonThe Triton telemetry buoy offers broadband data acquisition from sensors located on the buoy, suspended in the water column or on the sea floor, depending on application requirements. More Information → NautilusThe Fastwave Nautilus is an intelligent tracking unit. By utilising the Iridium satellite network, it enables tracking anywhere in the world. More Information →

NautilusThe Fastwave Nautilus is an intelligent tracking unit. By utilising the Iridium satellite network, it enables tracking anywhere in the world. More Information → XeosXeos designs and manufacture application specific telemetry and data collection products for environmental researchers, wildlife researchers and operational personnel. More Information →

XeosXeos designs and manufacture application specific telemetry and data collection products for environmental researchers, wildlife researchers and operational personnel. More Information → Ocean SonicsMeasuring ocean sounds is becoming an important part of meeting new legislation introduced in Europe, North America and Australasia intended to protect the oceans as development rises. More Information →

Ocean SonicsMeasuring ocean sounds is becoming an important part of meeting new legislation introduced in Europe, North America and Australasia intended to protect the oceans as development rises. More Information → DecimusDecimus® is an innovative detection and monitoring solution for system integrators working in acoustic monitoring. More Information →

DecimusDecimus® is an innovative detection and monitoring solution for system integrators working in acoustic monitoring. More Information → ChelseaChelsea Technologies Group specialises in the production of a range of innovative multi-parameter sensors & systems for monitoring the physical, optical & biological oceanographic and fresh water environment. More Information →

ChelseaChelsea Technologies Group specialises in the production of a range of innovative multi-parameter sensors & systems for monitoring the physical, optical & biological oceanographic and fresh water environment. More Information → SALTThe SonarBell is outwardly an unprepossessing device whose elegant use of materials technology has the potential to revolutionise underwater subsea asset location and even potentially reduce Dolphin bi-catch. More Information →

SALTThe SonarBell is outwardly an unprepossessing device whose elegant use of materials technology has the potential to revolutionise underwater subsea asset location and even potentially reduce Dolphin bi-catch. More Information → Vessel AISSRT has been a global leader in professional radio communication technology development since 1987, and since 1999 the world's leading developer of AIS technologies and products. More Information →

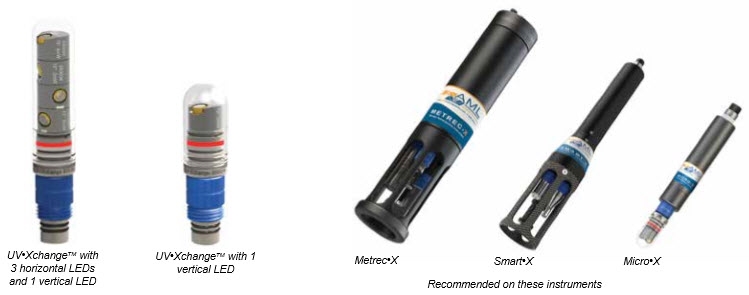

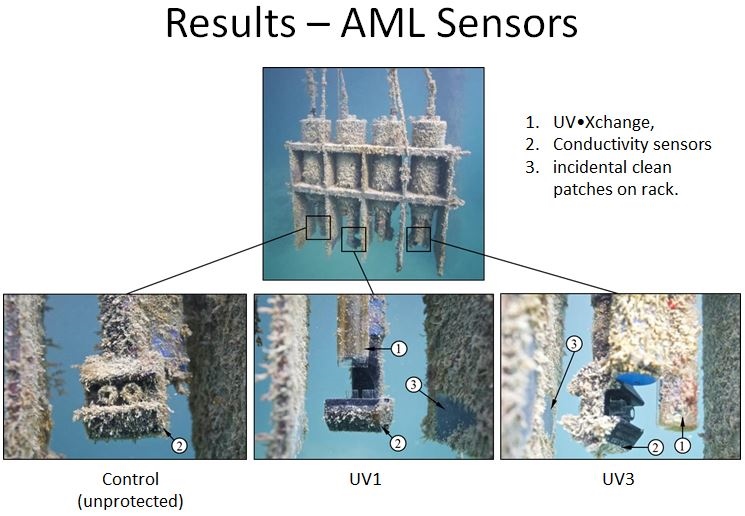

Vessel AISSRT has been a global leader in professional radio communication technology development since 1987, and since 1999 the world's leading developer of AIS technologies and products. More Information → AML OceanographicAML Oceanographic is an innovative manufacturer of Sound Velocity, CTD and Environmental sensors, probes and instruments. More Information →

AML OceanographicAML Oceanographic is an innovative manufacturer of Sound Velocity, CTD and Environmental sensors, probes and instruments. More Information → ASVASV (UK) designs, builds and operates unmanned marine systems for defence, oil & gas and research applications. More Information →

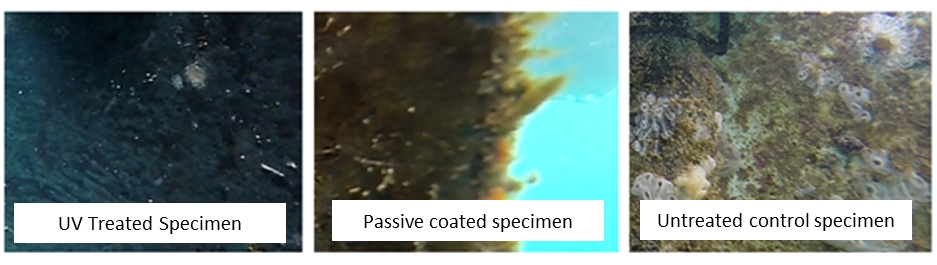

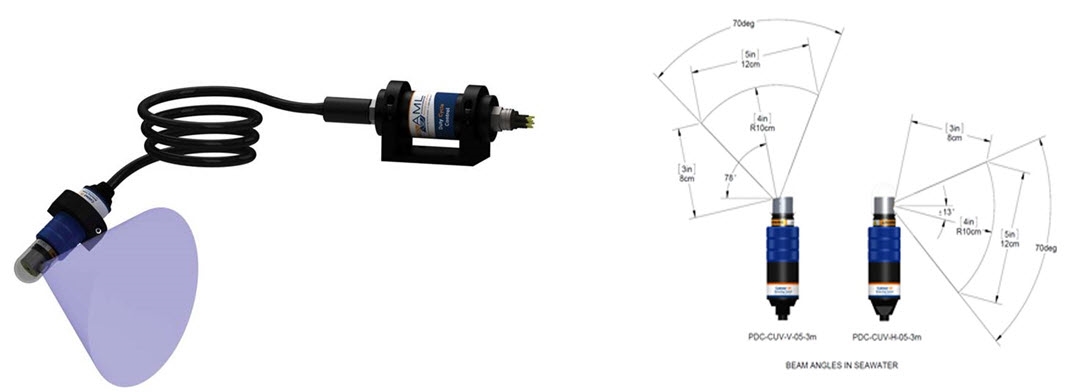

ASVASV (UK) designs, builds and operates unmanned marine systems for defence, oil & gas and research applications. More Information → Biofouling PreventionFastwave offers superior biofouling control products, capable of the prevention of biofouling on the ocean networks. More Information →

Biofouling PreventionFastwave offers superior biofouling control products, capable of the prevention of biofouling on the ocean networks. More Information →

-

-

Tracking

-

Vessel TrackingThe GTTS marine asset tracking solutions provide global real-time tracking and watch circle monitoring of marine assets such as vessels, barges, single point mooring buoys , unmanned platforms etc. More Information →

Aircraft TrackingFastwave offers low cost, portable aviation solutions to keep pilots and their passengers in constant global communication whilst in flight. More Information →

Aircraft TrackingFastwave offers low cost, portable aviation solutions to keep pilots and their passengers in constant global communication whilst in flight. More Information → Fleet Vehicle TrackingWhether you wish to track a truck convoy in Africa, a pipeline construction fleet in Australia or logging trucks in South America, Fastwave's remote vehicle fleet tracking and safety monitoring solutions can provide the answer. More Information →

Fleet Vehicle TrackingWhether you wish to track a truck convoy in Africa, a pipeline construction fleet in Australia or logging trucks in South America, Fastwave's remote vehicle fleet tracking and safety monitoring solutions can provide the answer. More Information → Personnel TrackingEnsuring the safety of personnel working or travelling in remote or potentially hazardous parts of the world is a challenge for many organizations involved in the mining, energy, construction, humanitarian and defense industries. More Information →

Personnel TrackingEnsuring the safety of personnel working or travelling in remote or potentially hazardous parts of the world is a challenge for many organizations involved in the mining, energy, construction, humanitarian and defense industries. More Information → Fastview Tracking SystemFastView is an award winning, online tracking and monitoring system that enables organisations to enhance the safety, security and efficiency of remotely deployed mobile assets such as vehicles, mobile plant, vessels and aircraft, as well as product data monitoring and tracking. More Information →

Fastview Tracking SystemFastView is an award winning, online tracking and monitoring system that enables organisations to enhance the safety, security and efficiency of remotely deployed mobile assets such as vehicles, mobile plant, vessels and aircraft, as well as product data monitoring and tracking. More Information → Mobile EquipmentIt is ideal for tracking high value, unpowered assets such as shipping containers, railcars, oceanographic buoys, barges and trailers. More Information →

Mobile EquipmentIt is ideal for tracking high value, unpowered assets such as shipping containers, railcars, oceanographic buoys, barges and trailers. More Information → Remote Tracking DevicesFastwave Communications specializes in developing GPS tracking solutions for organizations with mobile assets located in remote parts of the world. More Information →

Remote Tracking DevicesFastwave Communications specializes in developing GPS tracking solutions for organizations with mobile assets located in remote parts of the world. More Information →

-

-

Monitor & Control

-

Environmental MonitoringFastwave provides a variety of technical and telemetry solutions for monitoring any environment. We design these systems to monitor a variety of real-time data. More Information →

M2M & IndustrialFastwave has the engineering, telemetry and systems integration expertise to offer both off-the-shelf and custom remote monitoring and control solutions for SCADA systems and Machine-to-Machine (m2m) networks. More Information →

M2M & IndustrialFastwave has the engineering, telemetry and systems integration expertise to offer both off-the-shelf and custom remote monitoring and control solutions for SCADA systems and Machine-to-Machine (m2m) networks. More Information →

-

-

Telemetry

-

About IridiumIridium Satellite LLC is the only provider of truly global satellite voice and data solutions with complete coverage of the Earth (including oceans, airways and Polar Regions). More Information →

Iridium Satellite ModemsWe specialise in integrating instrumentation, sensors and control devices with Iridium satellite transceivers, so that data can be delivered or sent between any locations in the world within seconds. More Information →

Iridium Satellite ModemsWe specialise in integrating instrumentation, sensors and control devices with Iridium satellite transceivers, so that data can be delivered or sent between any locations in the world within seconds. More Information → Iridium Short Burst DataWe specialise in integrating instrumentation, sensors and control devices with Iridium satellite transceivers, so that data can be delivered or sent between any locations in the world within seconds. More Information →

Iridium Short Burst DataWe specialise in integrating instrumentation, sensors and control devices with Iridium satellite transceivers, so that data can be delivered or sent between any locations in the world within seconds. More Information → Iridium RUDICSWe specialise in integrating instrumentation, sensors and control devices with Iridium satellite transceivers, so that data can be delivered or sent between any locations in the world within seconds. More Information →

Iridium RUDICSWe specialise in integrating instrumentation, sensors and control devices with Iridium satellite transceivers, so that data can be delivered or sent between any locations in the world within seconds. More Information → Iridium Push-to-TalkWe specialise in integrating instrumentation, sensors and control devices with Iridium satellite transceivers, so that data can be delivered or sent between any locations in the world within seconds. More Information →

Iridium Push-to-TalkWe specialise in integrating instrumentation, sensors and control devices with Iridium satellite transceivers, so that data can be delivered or sent between any locations in the world within seconds. More Information → Iridium PilotWe specialise in integrating instrumentation, sensors and control devices with Iridium satellite transceivers, so that data can be delivered or sent between any locations in the world within seconds. More Information →

Iridium PilotWe specialise in integrating instrumentation, sensors and control devices with Iridium satellite transceivers, so that data can be delivered or sent between any locations in the world within seconds. More Information → Iridium EdgeWe specialise in integrating instrumentation, sensors and control devices with Iridium satellite transceivers, so that data can be delivered or sent between any locations in the world within seconds. More Information →

Iridium EdgeWe specialise in integrating instrumentation, sensors and control devices with Iridium satellite transceivers, so that data can be delivered or sent between any locations in the world within seconds. More Information → Iridium IoTWe specialise in integrating instrumentation, sensors and control devices with Iridium satellite transceivers, so that data can be delivered or sent between any locations in the world within seconds. More Information →

Iridium IoTWe specialise in integrating instrumentation, sensors and control devices with Iridium satellite transceivers, so that data can be delivered or sent between any locations in the world within seconds. More Information →

-

- News

-

Profile

-

About UsFastwave Communications develops integrated solutions designed to enhance the productivity, efficiency and safety of remotely located personnel, assets, infrastructure and equipment. More Information →

ContactWould you like to purchase or rent a device from us? Please contact us for more information about any of our products and we will get back to you as soon as possible. More Information →

ContactWould you like to purchase or rent a device from us? Please contact us for more information about any of our products and we will get back to you as soon as possible. More Information → PartnersIn order to provide a complete, "best in class" solution, Fastwave has established both formal and informal partnerships and strategic alliances with a number of innovative organizations with complementary products, services and expertise. More Information →

PartnersIn order to provide a complete, "best in class" solution, Fastwave has established both formal and informal partnerships and strategic alliances with a number of innovative organizations with complementary products, services and expertise. More Information → AwardsFastwave Communications Subsea Innovation, Technology and Standard of Excellence Awards. Fastwave have shown what local innovation can achieve in the global market. More Information →

AwardsFastwave Communications Subsea Innovation, Technology and Standard of Excellence Awards. Fastwave have shown what local innovation can achieve in the global market. More Information → CustomersFastwave has a well established client base covering a range of industry sectors, located in Australia and Internationally. More Information →

CustomersFastwave has a well established client base covering a range of industry sectors, located in Australia and Internationally. More Information →

-